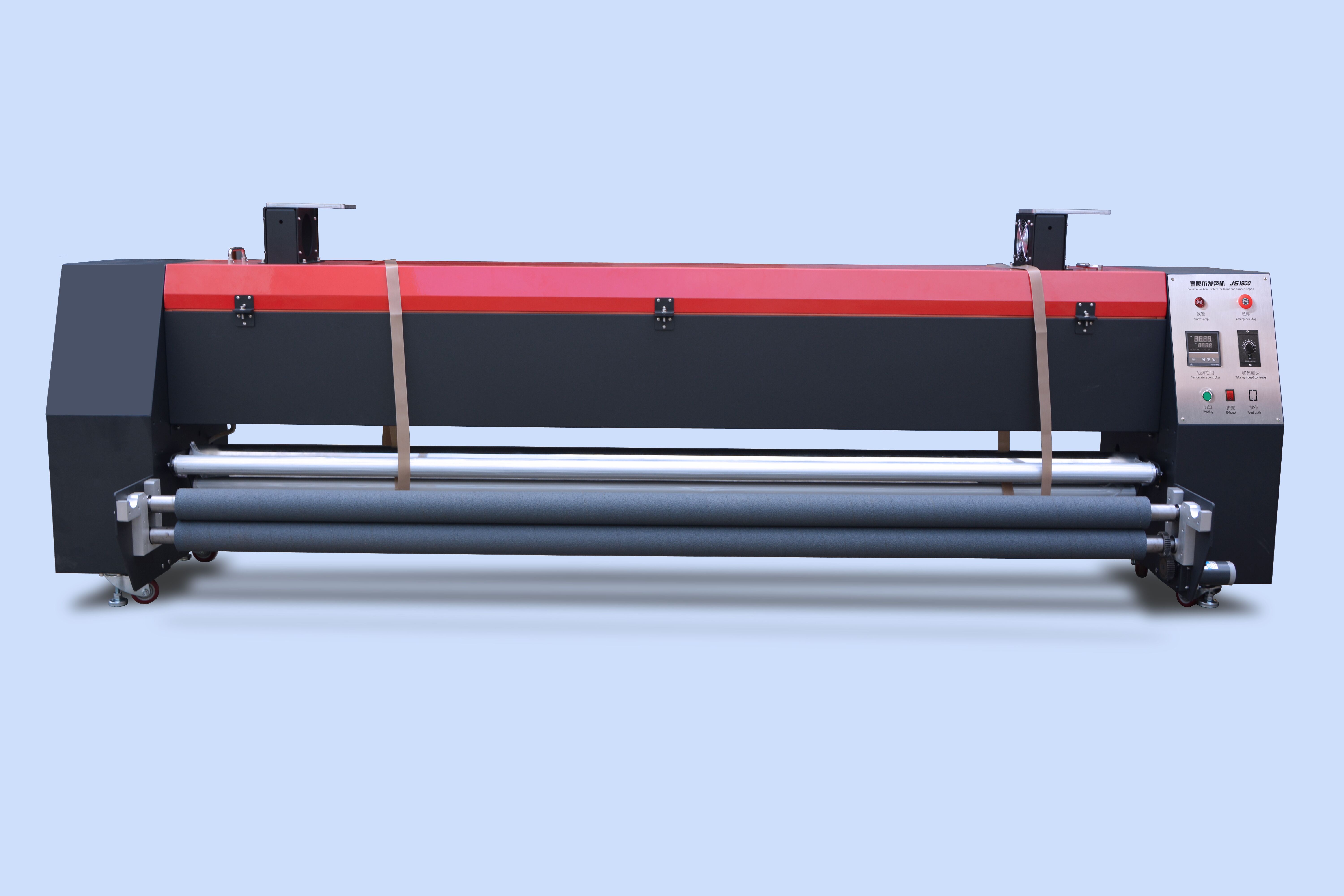

DESCRIPTION

Request for Quote*Far Infrared Blackbody Tube Radiation Electro thermal Heating

*Intelligent PID Temperature Control

*Digital Tension Control

*Feeding and Taking up Are synchronous

*Vacuum Fan Delivery Is Controllable

*Quick Tail Gas Treatment

*Convenient to Maintain

*Easy to Set up and Operate·Easy to load the media in and out oven during your machine working

*Easy to open the caver to clean inside of oven

*Special clutch to control the feeding up system working or stop , it’s ·easy for you loading the roll materials.

*Easy to change the active carbon from the filter

*Adopting the most advanced thermal energy technology low power consumption, saves electricity and conserve energy costs

*High Productivity

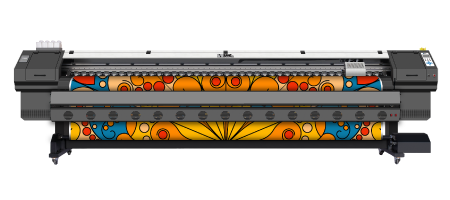

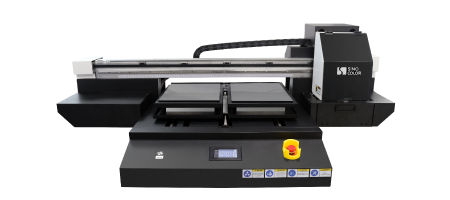

GALLERY

Specifications

| Power | 3.8KW | |

| Working Width | 1800MM | |

| Blackbody Tube Working Model | Far Infrared | |

| Heat Tuble Dimension | 2220MM | |

| Working Temperture | 100 to 250 °C | |

| Tension | 0 to 1.2Kg | |

| Working Voltage Take Up working Method Take Up media diameter(roll to roll) |

220~240V 50HZ Directly out or Roll to Roll. 300mm |

|

| Machin package Dimension | 2780X1330X870mm | |

| Weight | 320Kg | |

| Certification | CE Certificated | |

| Package | High intensity standard carton package Non Fumigation | |

| Available Printer | Mimaki, Roland , Mutoh and any Piazo Printer | |